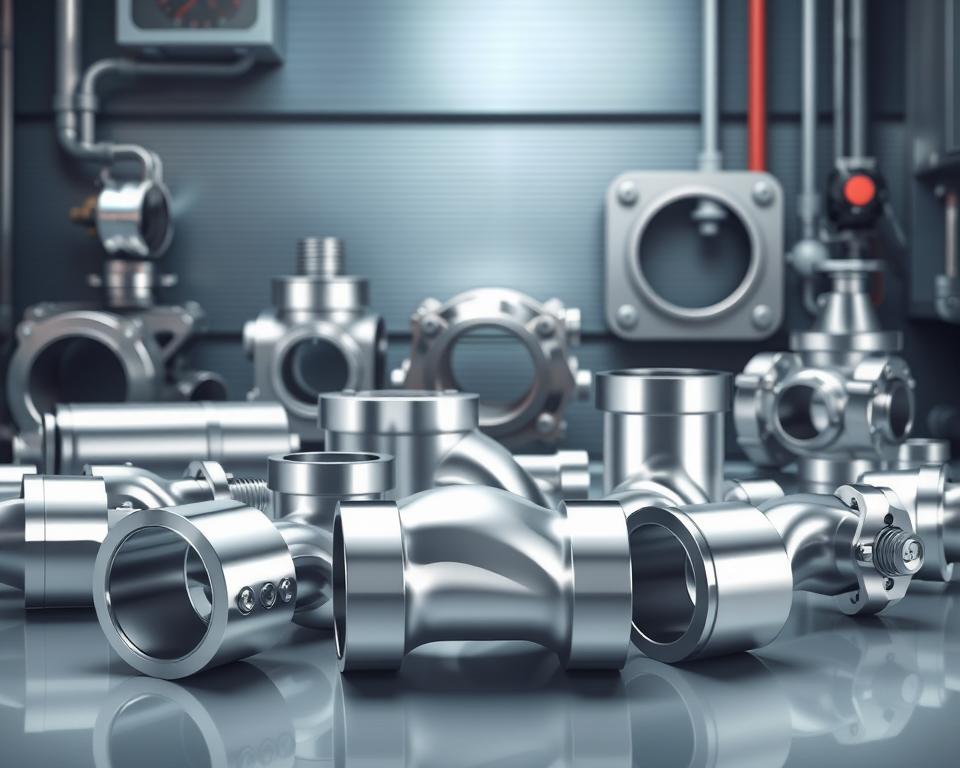

Advanced Tri Clamp Sanitary Connectors for Ultra-Clean Operations

Whenever hygiene is mission-critical, even tiny voids are significant. For this reason, companies like Installation Parts Supply focus on expertly engineered solutions built to remove hazards. These hygienic connection systems unite long-lasting strength with smooth installation, making them a top choice for sites that can’t afford compromises.

These elements provide more than preventing leaks – they’re built to meet the demanding demands of food manufacture, brew operations, and drug production. Forged from anti-corrosive alloys, they survive ongoing sanitizations while maintaining structural integrity. The development strategy parallels industry leaders like Alfa Laval, focusing on Tri-clamp fittings catalog smooth surfaces and fast release.

So, what makes them unique? Think single-hand use and wrench-free servicing. Technicians value the logical interface during fast-paced operations, while plant managers value standardized performance across pipelines. Every piece receives rigorous inspections to meet FDA and 3-A Sanitary Standards.

Main Insights

- Chosen by specialists for impermeable operation in critical environments

- Forged from high-spec stainless steel for extended service life

- Eases fulfillment of food safety and pharmaceutical codes

- Cuts stoppage through tool-free assembly and washdown

- Underwritten by QA systems matching global benchmarks

Solution Summary and Core Advantages

Dependable joints are the backbone of clean-room activity. Installation Parts Supply delivers components that combine accurate craftsmanship with operational practicality. Their assemblies supply zero-leak operation while making upkeep easy—critical for domains where rapid throughput meets sterility.

First-Class Quality and Clean Standards

Every product undergoes rigorous testing to meet global benchmarks. The materials withstand chemical attack, even after multiple CIP sequences. Seamless seals block pathogen buildup, a feature valued by dairy processors and pharmaceutical manufacturers alike.

These components parallel the standards of leaders like Alfa Laval, guaranteeing smooth surfaces and uniform dimensions. Modular formats fit into current lines, minimizing conversion fees. Operators see 30% quicker installs compared to traditional threaded systems.

Supplier-Specific Advantages

Bespoke machining separates IPS from competitors. Want an odd size or special coating? Their team partners closely with engineers to deliver custom parts. Immediate dispatch and 24/7 technical support keep production lines moving.

The perks reach beyond lifespan. Tool-free disassembly slims idle time during cleanliness checks. Beverage plants using these connectors observe fewer production stoppages and steady throughput. It’s not just about achieving compliance—it’s about going beyond without strain.

Technical Specifications & Design Features

Exact machining marries multi-purpose use in advanced facility setups. Installation Parts Supply builds components that merge exact measurements with customizable setups. Their mode guarantees seamless integration into existing setups while preserving stringent sterility standards.

Tailored Alloys and Textures

All installations vary. That’s why metals offered cover 304 as well as 316L, selected for strength and corrosion resistance. Surface treatments like electro-finishing create mirror-like smoothness, cutting microbial stickiness by up to 40% compared to standard finishes.

| Finish Type | Key Feature | Compliance |

|---|---|---|

| Electropolished | Ultra-smooth surface | ASME 3A, ISO 9001 |

| Mechanically Polished | Cost-effective shine | 3-A Sanitary Standards |

| Bead-Blasted | Non-reflective texture | FDA Food Code |

Manufacturing processes employ laser metrology to ensure uniform wall thickness. Tight tolerances (±0.005″) stop stress points in high-pressure environments. During quality checks, components face X-ray scans and pressure tests to spot microscopic flaws.

Customization reaches further than visuals. Clients seek specific angles, flange sizes, or purpose-built coatings for chemical resistance. These personalized selections help industries satisfy emerging guidelines without starting from scratch.

Application & Install Guide for Tri-Clamp Sanitary Connectors

Today’s fast-paced facilities need fittings that snap in promptly yet run dependably. These coupling sets shine in environments where quickness aligns with sanitation. Their design eliminates complex tools, allowing teams to retain focus on throughput rather than installation woes.

Quick-Install Workflow

Two flanged ends and a centered gasket establish perfect seals in seconds. Crew place the parts, position the locking ring, and tighten by hand – no wrenches required. This technique cuts fitting mistakes while holding steady load across the joint.

| Step | Traditional Method | Modern Solution |

|---|---|---|

| Alignment | Thread matching required | Flanged ends self-center |

| Sealing | Multiple tape layers | Single food-grade gasket |

| Securing | Torque wrench needed | Hand-tightened mechanism |

Versatile Bridges Across Equipment

From stainless steel tubes to processing equipment, these interfaces join varied parts with ease. The uniform design mates to various diameters, allowing quick reconfigurations during product changeovers. Dairy plants typically adopt them to change between cleaning cycles and production runs fluidly.

Maintenance teams favor how components separate for thorough sanitation. Smooth surfaces halt grime collection, while the smooth bore removes crevice dangers. Weekly cleanings consume half the labor compared to older connection methods.

Industry Applications and Compliance Standards

Covering brewpubs to immunization facilities, modern facilities depend on parts that fit varying demands while conforming to tight guidelines. Installation Parts Supply delivers solutions used across critical sectors where product purity is essential. Their designs tie output to standards, forging setups that work under strain.

F&B plus Pharma Fields

Inside culinary process sites, fast-shift couplings streamline hopping from batch to CIP. Breweries utilize tri-clover tees to manage complex flow paths without cross-contamination risks. Pharmaceutical manufacturers depend on airtight seals to protect sensitive compounds during sterile transfers.

These parts exist in numerous widths to match piping layouts, from micro facilities to bulk reactors. Dairy processors like how standardized parts shorten holds during equipment upgrades. Even small shifts in production processes are managed through modular designs.

Certification Under ASME-ISO-3A

Every product matches and outperforms benchmarks set by global organizations. ASME-certified materials tolerate pasteurization in pasteurization systems, while ISO-compliant finishes block germ adhesion. The 3-A symbol certifies compatibility for direct contact with consumables.

Tri-Clamp unions showcase the promise. Their uniform dimensions guarantee tight sealing across automated lines. Third-party audits validate supply chain from raw materials to finished goods, granting QC staff confidence.

By tracking these benchmarks, facilities simplify audits and earn approvals quickly. It’s not just about escaping sanctions—it’s about securing customer faith through transparent sanitation.

Final Insights and Next Steps for Your Sanitary Solutions

Choosing components that balance performance and compliance guides plant achievements. Installation Parts Supply provides systems blending strength and sanitation, granting leak-free performance across food, pharma, and beverage environments. Their products satisfy rigorous standards while simplifying daily workflows through simple fitment.

With options spanning stainless steel grades and custom finishes, solutions adapt to unique process requirements. Whether carrying thermal streams or constant washdowns, material choices and surface treatments extend lifespan. Professionals praise the vast catalogue of joints tailored to set velocity and line pressure.

Purchasing is simple, with expert guidance available to align line requirements. Same-day shipping and agile help reduce production stalls during upgrades or replacements. Regular service becomes effortless thanks to snap-apart unions and smooth surfaces that resist residue buildup.

Ready to enhance your facility’s reliability? Contact Installation Parts Supply to explore tailored configurations – from sanitary clamp to tri-clamp variants – backed by industry-leading quality assurance. Their team makes sure you satisfy today’s rules while gearing up for next-gen demands.